Pinch Valves

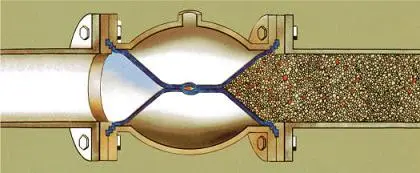

The very simple principle consists of an elastic sleeve which is compressed by a pressurized fluid (most often compressed air, possibly pressurized water) and which thus blocks the flow of the product carried inside the sleeve.

When the pressure between the valve body and the outside of the sleeve is released, the sleeve returns to its initial position, providing full passage, without restriction and without pressure loss.

Thanks to a fabric frame, the sleeve collapses when closed in a preferred direction.

A perfect seal is obtained, the grains or materials suspended in the fluid are coated in the sleeve without hindering its closure.

These valves are fully automatic and have multiple advantages:

Low weight.

High robustness and resistance to chemicals.

Safe to use.

Small footprint and easy assembly.

Economical to purchase and to maintain.

Effective in all situations: the fluid conveyed can be liquids, gases, dust, semi-solid materials, explosive products, etc.

Details

| Size: | DN 40 to 200 |

| Max. operating pressure : | 4 to 6 bars |

| Valve Body : | Cast Iron GG20 or aluminium |

| Clamping flanges : |

|

| Sleeve: | In function of support |

| Connection sizes : |

|

| Accessories: | Control and surveillance units |

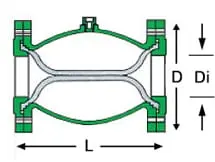

Dimensions of the PREMAFLEX pinch valve series PQVF

| DN | L | D | DI |

|---|---|---|---|

| 40 | 156 | 150 | 40 |

| 50 | 167 | 165 | 45 |

| 65 | 184 | 185 | 60 |

| 80 | 226 | 200 | 75 |

| 100 | 282 | 220 | 95 |

| 125 | 350 | 250 | 120 |

| 150 | 420 | 285 | 145 |

| 200 | 559 | 340 | 195 |