Heating cables for industry

Heating cables for industry must meet specific characteristics: – Resistance to corrosive atmospheres. – ATEX explosion-proof approvals. – Possibly approval for installation in nuclear power plants. – Withstands high temperatures. – Possibility of connection with industrial equipment.

We offer 3 types of heating cables for industry :

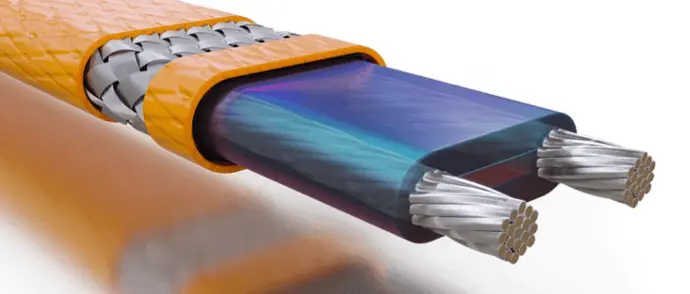

Self regulating cables

Self-regulating heating cables increase their power as the contact temperature decreases and this power decreases as the contact temperature increases.

Thermon manufactures a wide range of self-regulating heating cables suitable for industrial applications.

Used for metallic or non-metallic tanks and piping, these cables are easy to install for applications such as freeze protection and temperature maintenance.

Self-regulating heating cables:

BSX for protection against frost and temperature maintenance up to 65°C

RSX for protection against frost and temperature maintenance up to 65°C

RSX for underfloor heating

KSX for protection against frost and temperature maintenance up to 121°C

HTSX for protection against frost and temperature maintenance up to 121°C

VSX for frost protection and temperature maintenance up to 149°C

Constant power heating cables

The constant power heating cable has the particularity of developing the same power (Watt/meter) whatever the contact temperature or the length of the heating circuit.

This cable is made up of 2 conductors placed side by side and insulated from each other. A heating resistor is then wound around the 2 conductors and constitutes heating zones independent of each other (heating modules). All of the 2 conductors and the heating resistors are then covered with a new layer of insulation and, possibly, with a protective braid in stainless steel or tinned copper.

We offer constant power cables with different insulation depending on temperatures and type of installation: PFA – FEP – SILICONE – FIBERGLASS.

These cables have many advantages:

– ATEX explosion-proof approvals (depending on type).

– Simplicity of determination, manufacturing, installation.

– Installable on all metal or plastic pipes.

– Possibility of adjusting the length of the cable according to that of the pipe.

– Flexible cable in all directions.

– The constant heat emission rate makes it possible to precisely determine the temperatures of the heating wire.

- It also ensures a homogenous temperature over the entire length of the line.

The temperature controlled by the thermostat is considered representative for the entire heating zone.

Likewise, it is possible to precisely predict the time of:

- A climb in temperature.

– No variation in heating wire resistance with temperature.

- Calibration of devices

– Order can be determined precisely.

Cables with mineral insulation

This type of cable is essential for heating or maintaining very high temperatures.

Cable description :

Mineral insulated heating cables consist of a resistant core embedded in magnesium, compressed within a metal sheath.

Such a structure offers:

– thermal conductivity (3.5 W/m/°C) which allows excellent heat transmission.

– perfect sealing thanks to the presence of a continuous metal sheath which allows:

—. total immersion (in products compatible with the sheath).

—. installation in vacuum or high pressure enclosures.

—. crossing walls, a usually delicate operation.

– good resistance to mechanical and thermal stress.

The choice of the different cable components depends on knowledge of the actual operating temperature; this being directly linked:

. to the emissivity of the conductive body,

. to the conductivity coefficient of the insulation,

. to the external overall transmission coefficient,

. and at room temperature.

ELK-MI type heating cables are mineral insulated elements that solve the majority of high temperature heating problems up to 600°C and for voltages up to 500V. These elements are finished in the workshop.

Use cases :

– Heating of pipes and devices.

– Maintaining container temperature.

– Tank and hopper heating.

– Antenna heating.

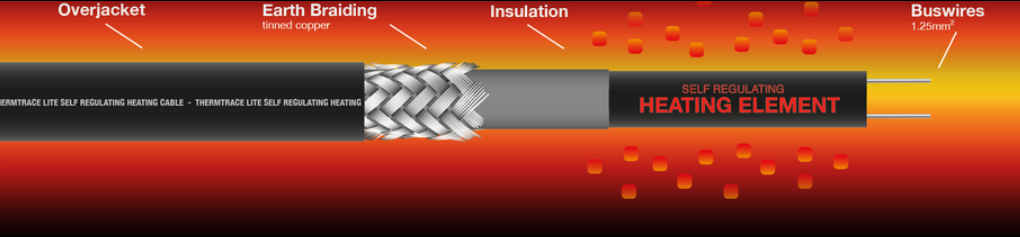

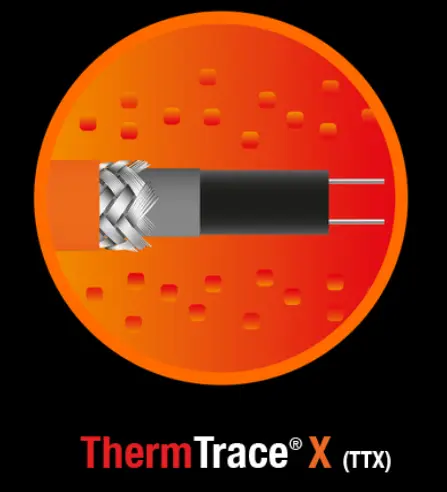

SELF REGULATING CABLE

Properties:

• Self regulating

• 5 power outputs

• Cut at desired lengths

• Resistant to chemical products

• For an extremely elevated temperature

Technical Specifications

Maximum exposure temperature (power off) : 250°C

Maximum operating temperature : 165°C

Nominal tension : 230V

Minimal bending radius : 25 mm

Minimal installation temperature : -60°C

Buswires: nickel plated copper

Applications

ThermTrace X is an industrial grade, self-regulating heating tape for extremely high temperatures. Its scope of application extends from freezing protection and maintaining the temperature of pipes and tanks in a large number of industrial applications and areas of exposure such as power plants or the chemical industry, petrochemical or oil and gas.

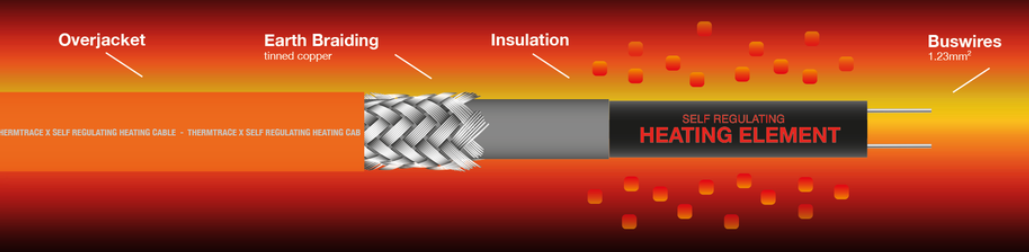

SELF REGULATING CABLE

Properties:

• Self regulating

• 4 power outputs

• Cut at desired lengths

• Resistant to UV

Technical Specifications

Maximum exposure temperature (power off) : 85°C

Maximum operating temperature : 65°C

Nominal tension : 230V

Minimal bending radius : 25 mm

Minimal installation temperature : -50°C

Buswires: nickel plated copper

Applications

ThermTrace Lite is an industrial grade, self-regulating heating tape designed for a wide range of applications. It can be used for freeze protection or low temperature maintenance of pipes and tanks in hazardous areas, as well as for heating roofs and gutters in the construction industry.

Properties:

Name | W/M | T° max. exposed | Dimensions |

12 TTL-2-BO | 12 | 85 | 10,5x5,6 |

23 TTL-2-BO | 23 | 85 | 10,5x5,6 |

TTL-2-BO : Cable with protective braid and thermoplastic oversheath

Soft heated covers and jackets

A range of flexible heated covers and jackets suitable for various applications:

Our technology allows us to design covers that adapt to all forms of media.

These covers are extremely flexible and particularly easy to install in areas with difficult access. The flexibility of the product allows excellent contact with the surface to be heated, thus resulting in temperature uniformity preventing the formation of hot spots.

- Valves in general

- Automatic Valves

- Pneumatic or electric transmitters

- Flow meters

- Counters, rotameters

- Sight glasses

- Local indicatros, pressure gauges

- Distribution clarinets

- Filters

- Various volumes

- Piping elements, fittings, flanges etc.

- Protection of equipment subject to flame or sparks

- Available for ATEX zones

What are the technical characteristics of the flexible heated jackets or heated mattresses?

- Maximum power : 4800 Watts/m²

- Supply voltage from 24 to 400 volts

- Design in siliconized glass fabric or aluminum coated glass fabric

- Non-magnetic construction if necessary

-

- Circuits chauffants de secours

- Isolation totale en fibre minérale ou céramique

- Œillets de fixation ou crochets incorporés pour faciliter le montage

How our heated jackets are made – the design

The outer shell of the mattress is made of appropriate canvases depending on the environment and temperature requirements. The interior envelope is chosen according to the temperatures of the product conveyed, taking into account attacks and dangers due to malfunctions. The heating wire is attached to the inner casing on the mattress side. The insulating material is enclosed between the two waterproof envelopes, the various parts of which are sewn watertight with flame-retardant threads. The mattress thus formed, previously formed for the device to be heated and/or insulated, is held in place using self-gripping strips making it easier to dismantle and reassemble. Each mattress can be equipped with a temperature probe.